Shipping

We ship Nationwide

Freightliner is a colossal vehicle brand with one of the longest backgrounds in U.S. commercial vehicle manufacturing history. It is also a recognized subsidiary of Daimler Truck North America, and its headquarters are based in Portland, Oregon. The major manufacturing facilities of Freightliner are located in a number of locations across the U.S., such as cities in Cleveland and North Carolina. All these broad manufacturing base set up by Freightliner shows its dedication to serving the North American trucking industry directly and efficiently.

For the last 80 years, Freightliner has continuously been on the cutting edge of trucking innovation with a heritage of building trucks that maximize fuel economy and improved safety features along with greater returns on investment. Their comprehensive product range includes trucks of Class 5-8 across many configurations, and they’ve addressed the application needs ranging from on-highway long-haul to vocational applications, including construction and refuse collection.

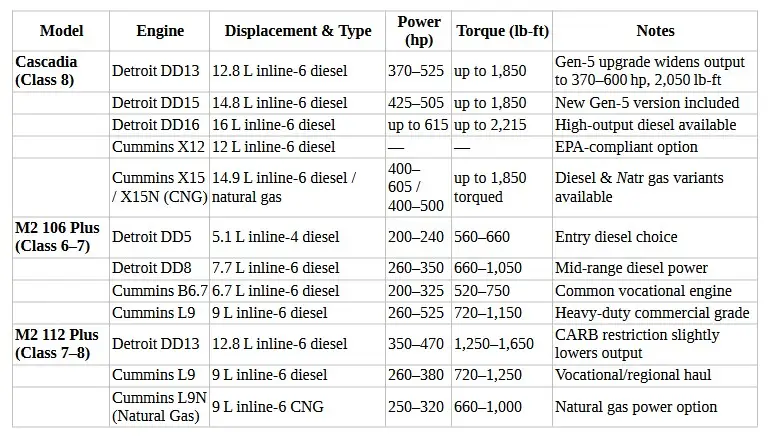

Let me think about the following example: in the United States, Freightliner Cascadia is the undisputed champion and best-selling unit. As a Class 8 heavy-duty truck, the look is aggressive, with aerodynamic features to save fuel. Cascade also boasts a driver-centric interior, with innovative safety systems like Detroit Assurance; several engines are also available, including the new Cummins X15N natural gas engine. Its popularity stems from it being a combination of comfort, dependability, and affordability, which puts it in favor among the majority of fleets and owner-operators equally across North America.

Used Freightliner Engine’s Compatibility: Freightliner owners in search for engine replacement against their current one should verify and replicate the specifications of their engine with the new one. This information is vital for an easy placement of the used engine. Freightliner owners also have to make sure the make and model of their Freightliner's vehicle matches with the used engine’s Electronic Control Unit (ECU).

Detailed Examination prior to payment: It has been observed common engine flaws like oil leaks, corrosion & rust, physical damage, and neatness can be seen easily. Freightliner owners could identify the quality of engine if they turn it on and listen for the cold start, idle sound, and rev sound produced by the engine.

Prefer to purchase the Grade-A Freightliner's Engines: Low mileage for a Freightliner engine under 20,000 miles is ideal, but a slightly older engine with a full-service history can also turn out to be a smart choice.

Call for most recent Service Records of the used Freightliner’s engine: Previous ownership records and past service history of the certified Freightliner engine should be requested as they can tell how well the engine has been cared for! It will also show whether the engine was involved in an accident and how well it was stored?

Purchase your next Freightliner’s engine from Reliable sources: Buying a used Freightliner transmission from trustworthy sources like us helps lessen the risk of getting a bad or low-quality engine. Freightliner’s owners can always check our customer reviews and ratings before making a verified purchase. Our 24/7 customer service team is always accessible for all your important queries and discussions.

Examine the warranty given on Freightliner’s used engines: We have been giving warranties on all the sourcing of used Freightliner engines completed through our website or on call. You can check with our customer service team for return policies on the certified Freightliner engines delivered.

Best Price Assurance on Freightliner’s engines: Freightliner owners can compare the prices offered on this website with other sellers online and we’ll offer the best price; taking into account engine condition, mileage and service history. We regularly come up with great bargain deals on our website that significantly lower the buying price of certified Freightliner Engines.

Making a business deal for a used Freightliner transmission can turn out to be a logical decision, especially when you’re comparing its price with a brand-new Freightliner’s engine. Here are the primary reasons why:

Low Prices of Old Freightliner Motor: It’s one of the perception that Freightliner owners go for buying used Freightliner engines as they make big savings on the purchase of new ones. Second-hand Freightliner engines are comparatively less expensive and if they’re adequately maintained, they become a great choice for price-conscious customers.

Large quantities offered for used Freightliner engines: Used Freightliner transmissions are offered in abundance of Freightliner heavy truck models. With such expansive use, second-hand Freightliner engines are easily available, with buyers having a large number of pieces to pick from.

Proven trust-factor of Freightliner’s refurbished engines: Freightliner is acclaimed for making engines that are rugged and dependable. Most of the Freightliner engines are built to have strong proficiency, so they become the first choice for buyers in search of reliability.

Easy and Anywhere Servicing of used Freightliner engines: Freightliner engines are robust and with a focus on easy and anywhere servicing, the maintenance and repairs is never an issue for a good mechanic. If these engines are routinely serviced over the years, a used Freightliner engine keeps delivering good performance in return.

Sizeable Aftermarket services for Freightliner engines: The aftermarket support for Freightliner engines is quite voluminous, with huge number of replacement parts and accessories easily available. They range from OEM parts to aftermarket performance upgrades that will provide an array of options for customising and tuning a used Freightliner engine to fit one's style of driving.

Whenever you’re purchasing an original used Freightliner motor, it is advisable to follow a holistic approach to ensure that you will procure a reliable piece. Here's a meticulous approach combining key factors:

Fitness Confirmation of the used Freightliner Motor: If looking to buy an old Freightliner engine, one must do a complete check for any signs of wear and tear, damage, leaks, or rust, as they might affect the engine's performance. Make genuine efforts to inquire for visible signs of defects that may affect the Freightliner engine’s performance.

Distance covered of the Certified Freightliner Motor: Always check the mileage run of the second-hand Freightliner engine and select those engines with lesser mileage, as they will have a lesser wear & tear and thus have a better prospect of longevity and better performance. Grade A Freightliner engines sold by us have always shown better performance and lasted much longer.

Accomplished Freightliner Sellers only: Getting a used Freightliner engine from a well-established source with a good background like ours always places lesser risks for picking up an engine of poor quality. You can always check out our customer reviews and ratings before making an authenticated Freightliner purchase. Our Customer Service Team is here to help you with all your important queries and concerns.

Over-and-above Engine Installation Fees: Here, additional fees of installation the certified Freightliner engine, such as labor, parts, or modifications needed, should be checked and added to the total cost as they can make significant escalations to the cost of the used Freightliner engine.

Gaps in prices of used Freightliner Engines: Always verify and compare prices of different used Freightliner transmissions on parameters such as engine condition, warranty, and mileage. A lower run Freightliner engine may not be a good option if its condition is miserable.

Warranty given on pre-owned Freightliner engines: We have been offering warranties on all the purchases of used Freightliner engines completed through our website or on call. You can check with our customer service team for return policies on the used Freightliner engines delivered.

Freightliner Koleos, Kadjar, Clio, Captur Engines – In Stock Now and Ready to Ship! Get your luxury ride back on the road with our affordable Freightliner engine swaps. Each unit is reliable and performance-tested, ensuring smooth power delivery.

Choose certified used Freightliner engines, meticulously inspected and backed by warranty and support for ultimate peace of mind. Benefit from fast shipping with nationwide delivery on all our used Freightliner engines for cars and SUVs – all models available.

Shipping

We ship Nationwide

Warranty

Refund and Replacement

Safe Shopping

Payment 100% secure

Support

Contact us 9AM to 5PM EST

5k+

Happy Customer

20k+

Engines & Transmission Sale

56+

Inventory Yards

A Grade Parts

We Deals in Only

The "best" Freightliner transport engine depends on the application and preferences, but Detroit Diesel's DD15 engine is much assessed for fuel efficiency, strength and balance of reliability in long-neck fractures. DD15 provides excellent fuel economy, meets emission standards and has advanced facilities as integrated control for customized performance.

Many Cascadia drivers show the engine hours in the information center, which are available through the dashboard button - navigate through the menu to find "motor time" or "service lessons". Alternatively, adding a diagnostic scanner that is compatible with the Detroit Diesel or Freightliner system will provide an accurate motor reading with other maintenance data. The surveillance engine helps to plan regular service and track engine use.

The motor derate by a Freightliner when the motor control module detects an error or position that can cause damage or unsafe operations, so it reduces the engine's power for protection of motor and emission systems. This beam shortage helps prevent further damage, but limits the vehicle's performance, often indicated by warning lights or messages on the dashboard. General causes include sensor errors, emission system problems or important engine problems. Immediate diagnosis and repair are needed when scared.

Stopping the engine shutdown involves deactivation or adjusting a passive shut -off hours through the dashboard menu of the vehicle or with a clinical tool. On some Freightliner models, you can navigate the Driver Information Center to find the cutting of Idol shutdown and increase the permissible passive time or fully disable the convenience. If this option is not available, it may be necessary to reprogram ECM parameters to diagnostic scanners such as Detroit Diesel Diagnostic Link (DDDL). Remember that disabling passive closure can increase fuel consumption and emissions.

A yellow motor light on a Freightliner is a warning indicator indicating that the engine or emission system has detected an error that needs attention, but is not immediately important. This acts as an initial warning of potential problems such as sensor errors, irregularities in the emission system or maintenance requirements. The light encourages early inspection and repair to prevent more serious problems or increase the engine.

Freightliner Cascadia is usually equipped with several diesel motor options, mainly from caterpillars in Detroit Diesel, Cummins and sometimes older models. Popular motors include DDD13, DD15 and DD16 engines, which are inline 6-cylinder diesel engines designed for fuel efficiency, reliability and power from around 350 to 600 horsepower based on models. Cummins isx15 and X15 engines are also widely used for their power and durability. The choice of motor depends on the specific model year, customer preference and regional rules.

Freightliner uses different engines based on truck models and applications. General engines include DD13, DD15 and DD16 series Detroit Diesel, known for advanced fuel efficiency and power output, which is a long -lasting truck. Cummins engines such as ISX15 and X15 are also widespread, preferred over their shelf life and power area. Some old freight models had larva engines. The engine selection depends on factors such as vehicle configuration, customer requirements and emission standards.

Resetting the check motor light on Freightliner Cascadia is done with a strong tax diagnostic scanners such as Detroit Diesel Diagnostic Link (DDDL). Connect the scanner to the diagnostic port, scan a system and cleared error code. This check recites the motor light. Note that if the underlying problem remains, the light will return. It is not recommended to disconnect the battery due to electronic system complication and can cause loss of other data or settings.

When a Freightliner-engine stops for regeneration, this diesel particle -shaped filter (DPF) undergoes a process called regeneration, which burns the soot building in the exhaust system to reduce emissions. During this time, the engine can increase the temperature and run at high turns. Drivers should avoid closing the engine during regeneration, continuing to keep the vehicle safe and allow the process to complete. Disruption of regeneration can lead to a reduction in errors or performance. If frequent regeneration occurs, it may indicate the need for service to motor or driving pattern problems.

To use motor brakes (Jake Brake) on Freightliner, you must first make sure the vehicle has a safe speed and conditions are appropriate. Find the engine brake switch on the dashboard and turn it on to activate the system. The engine helps to slow down the truck by switching exhaust valve time to reduce the engine speed without using a brake brake, increasing control over the fall. Many trucks also have adjustable motor braking settings to separate brake intensity. Always use motor brakes in accordance with local rules and road conditions.

The factory may not come with the engine brake installed as the factory standard due to 2014 Freightliner Cascadia Customer options, motor options or specific configurations. Some models rely on alternative braking systems, such as compression release motors, exhaust brakes or jake braking options sold separately. In addition, regulations or preferences may cause the raft to get out of the engine brake. However, many Cascadia offers motor brakes as an option or standard on some motor packages, so ABSON